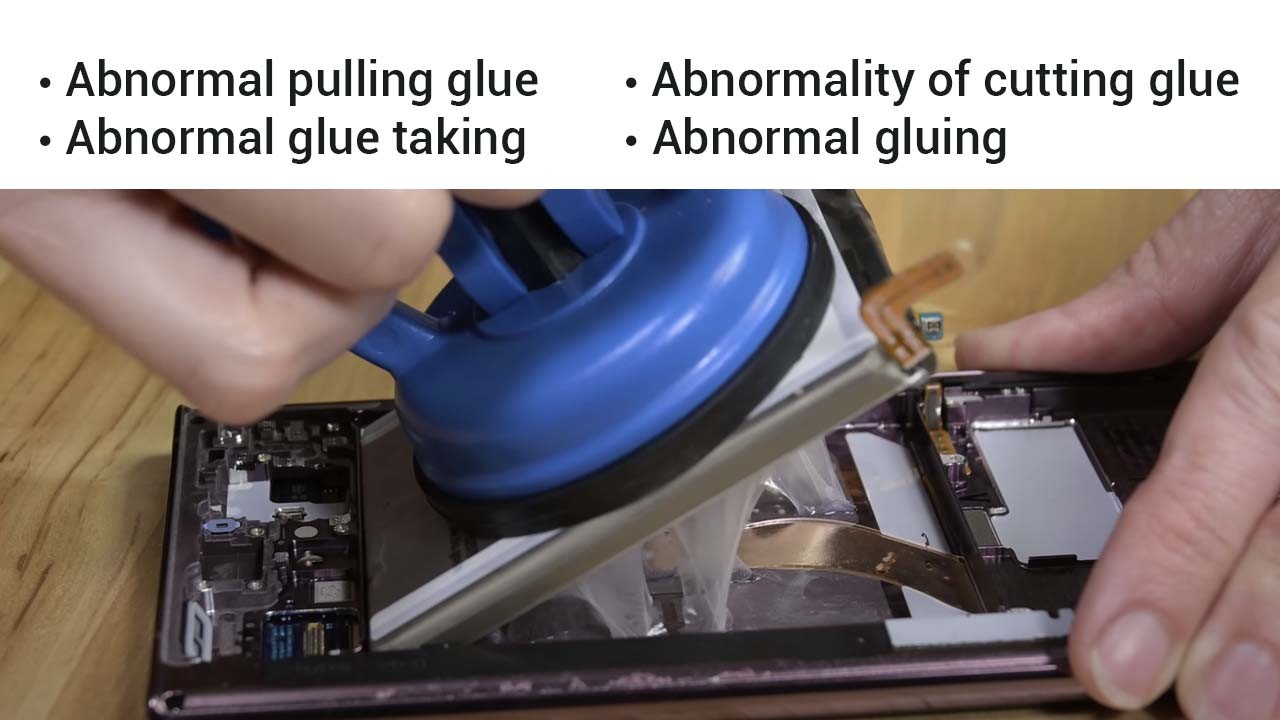

An essential step in the assembly of lithium batteries is the use of glue. It is frequently seen in the following applications: welding printing and polar ear root gluing after ultrasonic welding, tying multiple cells after matching, welding after welding gluing after welding of connecting pieces, core bundling, gluing after wrapping Mylar, etc. Numerous unusual issues frequently arise during the gluing process because of the viscosity of the glue itself and the thin thickness of the glue paper.

I. Abnormal pulling glue:

1. If pulling on the glue is impossible, meaning that the glue clip claws are not clamped in the glue, pulling will be empty.

Analysis of Reason:

a) The tape was not properly pressed after the final glue cutting, which caused the tape to come back.

b) The glue clamp claw was broken or damaged, making it impossible to clamp the glue.

The solution is to individually check each glue cylinder to see if the pressure is abnormal, to make sure the cylinder is positioned correctly, to see if there is a glue issue, to see if the glue clamp claw is damaged, and, should an issue arise, to fix it as soon as possible.

2. Inadequate drawing, where the tape comes loose from the claws while the drawing is being done, or where the drawing length is not up to par.

Analysis of Reason:

a) The pulling glue is in the shape of an abnormal cylinder.

b) The film has abnormal tension, making it impossible to pull the glue or causing the adhesive paper to rebound.

Solution: It is advised to pull the glue using a servo module, as this makes it easier to adjust the pull’s accuracy and troubleshoot its length. The pull’s tension is guaranteed by tightening the unwinding mechanism. The unwinding tension can also be managed with the magnetic powder clutch.

II. Abnormality of cutting glue:

Cutting the glue and taking out the tape while doing so is the main performance.

Analysis of causes:

a) The cutter has a short lifespan and is easily penetrated, which leads to continuous glue.

b) The cutter’s ability to control the cylinder force is inadequate.

The following are the solution measures:

a) The cutting knife is made of titanium alloy, and it is advised to use a scalpel because it is easy to install and replace.

b) The program counts the number of times the cutting knife is used, and it automatically reminds the user to replace and grind during the grinding period.

c) The cylinder diameter selection requirements are ≥ 25mm.

III. Abnormal glue taking:

It is mainly manifested as glue vacuum alarm, glue drop, etc.

Cause analysis:

a) abnormal vacuum flow.

b) the suction head is not attached to the adhesive paper.

c) the vacuum opening and closing time do not match the glue action.

Solution: The abnormal vacuum flow can be judged by checking the value of the vacuum meter. It is recommended that each vacuum should be set up with an independent vacuum meter in the design of the equipment to facilitate the troubleshooting of problems. It is recommended to use an embedded vacuum suction cup for the suction head, and the measured effect is better than the pinhole suction head.

IV. Abnormal gluing:

The tape is taken up after gluing, the tape being folded, the gluing position deviation, etc. are the main manifestations.

The primary causes are as follows:

a) the glue head’s design flaws cause the suction to be unstable.

b) glue residue builds up in the suction head, causing the glue phenomenon; and

c) the glue mechanism uses a cylinder type, which reduces accuracy.

Solutions include: a) avoiding the problem from the start, designing the suction head in accordance with the specifications of the process, and using a servo module to guarantee the stability and accuracy of the glue removal; and b) using on-site equipment to clean the suction head and drawing mechanism regularly to make sure the tape is not sticky.

Conclusion

Gluing in lithium battery assembly, though vital, is prone to issues like pulling, cutting, taking, and application abnormalities. This analysis pinpointed root causes for each – from worn cutters to suction head flaws – and offered solutions – like servo modules and embedded suction cups. By implementing these recommendations and prioritizing equipment maintenance and design, battery assembly lines can achieve smoother, more efficient gluing, leading to safer, higher-quality batteries.