Welcome to the exciting world of electric vehicles (EVs)! These sleek machines are revolutionizing transportation, offering a cleaner and more sustainable future on wheels.

But have you ever wondered what powers these marvels of engineering?

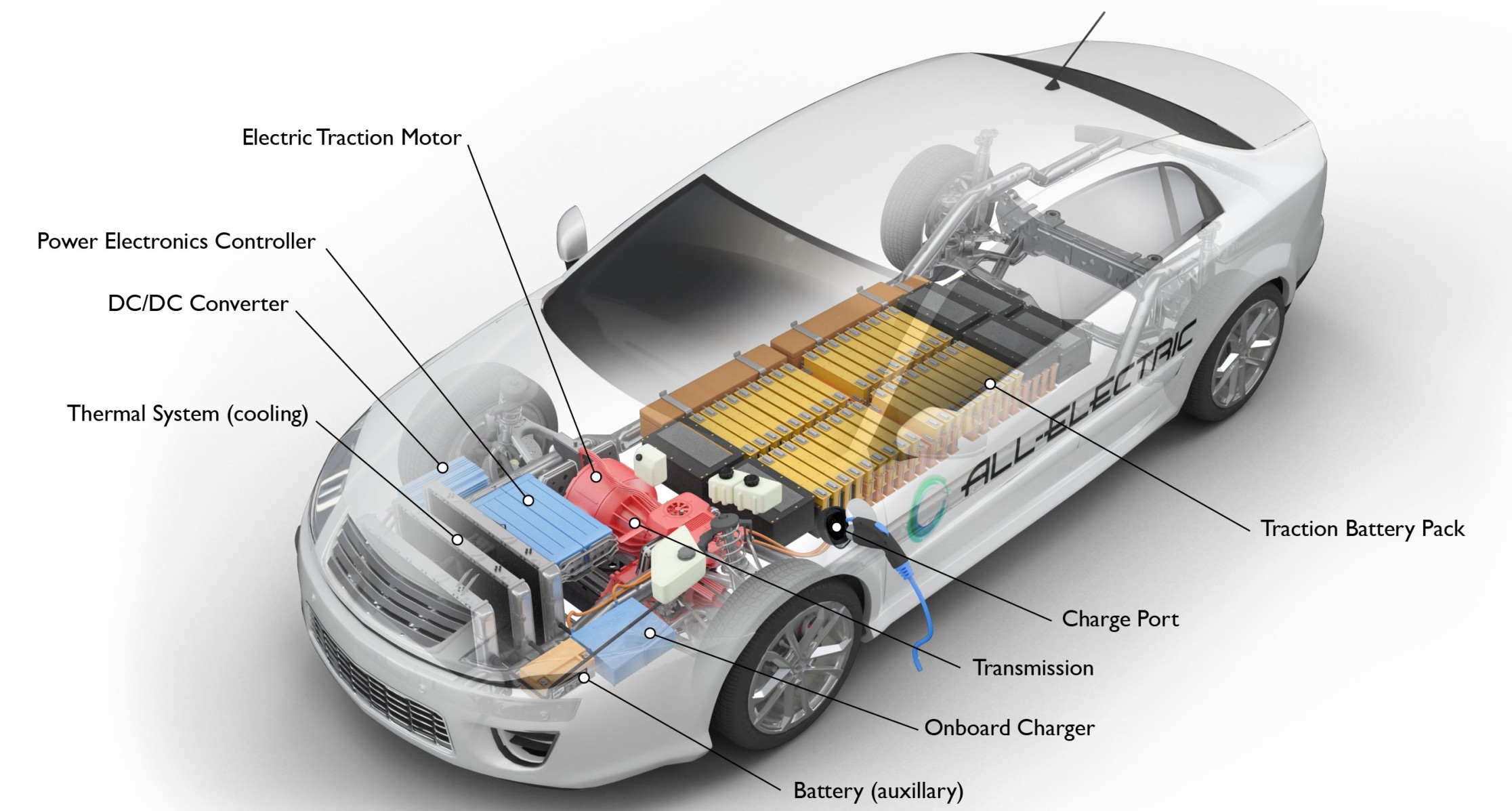

Let’s dive under the hood and explore the essential components that make an EV tick.

- Motor

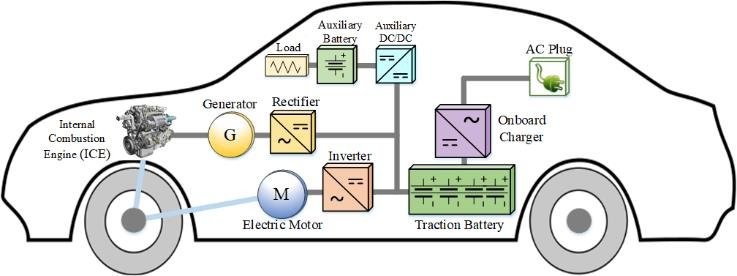

An electric vehicle’s power source is its electric motor. It is an electromagnetic device that uses the electromagnetic induction principle—represented by the letter M in the circuit—to convert electrical energy. Its primary purpose is to produce rotational motion in order to supply energy for various machinery or electrical equipment.

- Generator

The main function of the generator is to convert mechanical energy into electrical energy.

- Cooling system

Radiators, pumps, fans, thermostats, coolant thermometers, and water discharge switches are the typical components of a cooling system. Air cooling and water cooling are the two cooling techniques used in electric vehicle engines. Water is typically used to cool the engines of electric vehicles.

- Transmission system

The battery car’s transmission system does not require a clutch or transmission because the pure electric vehicle’s motor has good traction characteristics. The speed regulation system allows the controller to adjust the motor’s speed, thereby achieving speed control.

- Driving system

The driving system, which primarily consists of frames, axles, wheels, and suspensions, is comparable to that of fuel-powered automobiles. In order to maintain the proper operation of the entire vehicle, the electric vehicle driving system’s function is to receive the torque transmitted by the motor through the transmission system and create traction on the road through the adhesion between the driving wheel and the road surface. To ensure the regular operation of electric vehicles, it should also minimize the impact and vibration caused by the uneven road in the face of the body.

- Steering system

The function of the electric vehicle steering system is to maintain or change the driving direction of the electric vehicle. It includes components such as steering control mechanism, steering device and steering transmission mechanism. The steering wheel, steering gear, steering knuckle, steering knuckle arm, cross rod, straight pull rod, etc. are the parts that make up the steering system.

It is essential to make sure that the steering wheels of electric vehicles have a coordinated corner relationship. The driver can maintain the electric vehicle in a straight line, turn, or alternate between the two aforementioned moving states by manipulating the steering system. Additionally, it makes sure that the steering wheel is sensitive, does not swing, self-vibrate when in driving position, has a small minimum turning diameter, and operates lightly.

- Brake system

All electric vehicle braking, and deceleration systems are collectively referred to as the “braking system.” Its purpose is to either keep the stopped electric vehicle motionless or lower the speed at which it is driven. Both brakes and brake transmission components are part of the brake system.

Modern electric vehicles also have brake anti-lock devices installed in their braking systems. Pure electric cars have two sets of braking systems: driving and parking. This is similar to the braking systems of fuel-powered cars.

- Electrical equipment

Batteries, generators, lighting lamps, instruments, audio devices, wipers, etc. are among the common electrical components found in electric vehicles.

The battery’s job is to provide the motor and starter with electricity. Pure electric vehicles typically use multiple 12V or 24V battery series and parallel power battery packs as the power source in order to meet the high voltage requirement of electric vehicles.

The power battery pack has a voltage of between 155 and 400 volts, to which periodic charging is added. A pure electric vehicle’s power battery pack is its most important component. Its own weight, volume, and capacity to store power all have a significant effect on how well pure electric vehicles operate.

A significant portion of the pure electric vehicle’s effective loading space is occupied by the power battery pack, which presents a challenging layout challenge. To maximize the useful space on the vehicle’s chassis, the power battery group is separated into multiple “groups” that are dispersed throughout the frame and subsequently connected in series. For ease of installation and disassembly, the most popular arrangement for a pure electric vehicle is to place the power battery pack under the floor.

- Energy Recovery System

The energy recovery system’s job is to transform the inertial mechanical energy used by the electric vehicle during braking or sliding into electrical energy. This energy is then stored in the capacitor or used to charge the power battery, which releases energy rapidly when the vehicle is moving.

- Heat dissipation system

A strong heat dissipation system is essential for both the safety of electric vehicles and the longevity of their batteries because batteries produce a lot of heat when the vehicle is operating.

- Body

The front and the carriage are the two sections that make up the body. A driver and a co-pilot can typically fit in the front portion of the vehicle. The carriage’s configuration, materials, space design, and other features are changed to suit the needs of the customer. Electric vehicles typically have one or more single seats arranged side by side to maximize passenger comfort; the exact number of seats varies depending on the model.

- Industrial installations

Industrial components, such as lifting devices, door frames, forks, etc. of electric forklifts, are specifically arranged for industrial pure electric vehicles to fulfill the operation requirements. Usually, the hydraulic system powered by the motor completes the tasks of lifting the fork and tilting the door frame.

For More Updates Follow Us

WhatsApp – Facebook – Instagram – Twitter – LinkedIn – YouTube